Epoxy Flooring Louisville KY

Fill in your details below - we'll reach out to schedule a free quote!

We will get back to you as soon as possible

Please try again later

Epoxy Flooring Louisville KY

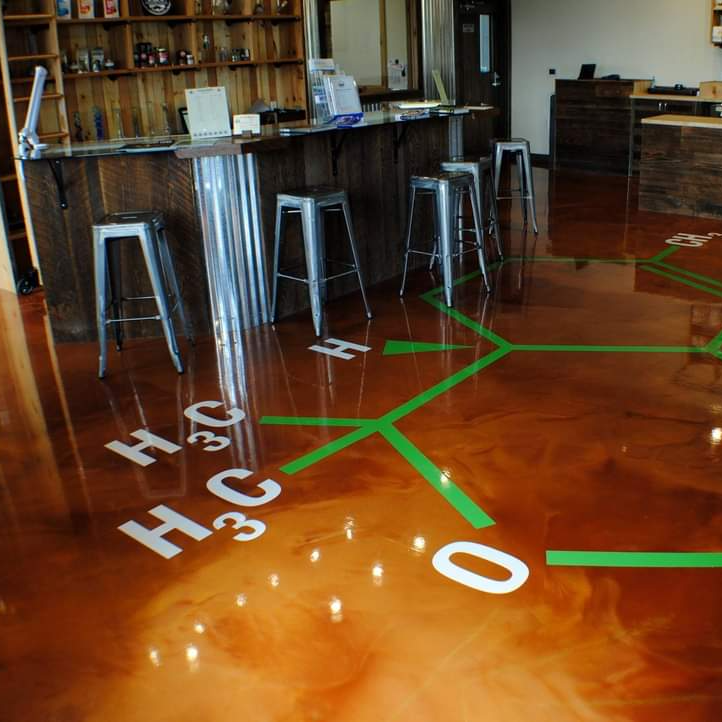

JD Flooring specializes in the installation of custom epoxy flooring in Louisville KY. No matter what your epoxy flooring needs are, our team of experienced professionals can help.

We have installed all different types of epoxy floors in a number of different settings, so we know how to create a custom solution that will meet your specific needs.

Whether you need a durable floor for a high-traffic area or a decorative floor for a more aesthetic setting, we can help.

Contact us today to schedule a consultation to discuss your custom epoxy flooring needs.

Local Epoxy Floor Company Louisville

JD Flooring is made up of local flooring installation contractors in Louisville, KY.

We have years of experience in the business and know the area well.

The climate in Louisville is perfect for epoxy flooring installations, as it doesn't get too cold in the winter or too hot in the summer.

We also offer a variety of other services, including: carpet installation, hardwood flooring, laminate flooring, tile installation, and more.

If you're in need of any flooring services, we're the company to call!

Louisville Epoxy Flooring Contractors

JD Flooring is made up of a group of professional epoxy flooring contractors who specialize in installing epoxy floors.

We are based in Louisville KY, and we have been in business for many years.

We have installed epoxy floors in a wide variety of commercial and industrial applications, and we're experts in the field.

If you are looking for a high-quality, durable, and attractive flooring solution, then epoxy flooring is the perfect option for you.

Our team of experienced professionals will work with you to ensure that your floor is installed correctly and looks great.

Epoxy Flooring Company Louisville KY

Our contractors are passionate about their work and spend time learning more about epoxy each day.

With their skills and knowledge, they can get the job done right.

In addition, they are always available to answer any questions you may have about epoxy flooring.

No matter what your epoxy flooring needs are, our team of experienced professionals can help.

What are Epoxy Floors?

Epoxy floors are a type of flooring that is made from a resin system.

The system includes two components: the epoxy and a hardener.

When these two components are mixed together, they create a chemical reaction that causes the mixture to harden.

Once the mixture hardens, it forms a strong, durable bond that can last for many years.

Epoxy floors are often used in commercial and industrial settings because they are able to withstand heavy traffic and wear and tear.

They are also easy to clean and maintain.

Epoxy Floor Installation Process

Epoxy flooring installation can be a complicated and scientific process.

Our team of experienced professionals will work with you to ensure that your floor is installed correctly and looks great.

We'll describe our process in the following section.

Choose an Epoxy Flooring Solution

The first step in the epoxy flooring installation process is for the customer to choose the type and style of epoxy floor they want.

Once the customer has chosen the type of epoxy floor they want, the next step is to select the color.

Epoxy floors are available in a wide range of colors, from dark to light, and everything in between.

The customer can also choose to add a variety of design elements to their epoxy floor, such as logos or patterns.

The sky is the limit when it comes to designing an epoxy floor.

Material Preparation

The second step in the epoxy flooring installation process is material preparation. This includes getting all of the tools and chemicals together on the work site to ensure a smooth installation process.

The most important tool for this step is the epoxy resin itself. The resin is mixed with a hardener, and the ratio of these two components must be carefully measured to ensure the finished product will have the desired properties.

In addition, a variety of other tools and materials are needed, such as rollers, trowels, and tape.

Once all of these items have been gathered, the surface must be prepared for the epoxy by cleaning it thoroughly and removing any loose debris.

Measurements & Calculation

The third step in this process is taking precise measurements and calculating how much epoxy will be needed.

It's important that we triple-check our figures in this stage, because a mistake here could mean that we don't have enough epoxy to finish the job.

That's why we take such care in this stage of the process.

With so many years of experience in the industry, we know what it takes to get the job done right.

Room & Climate Preparation

The fourth step in the epoxy flooring installation process is room & climate preparation.

This is arguably the most important step in the entire process, because it will determine whether or not the epoxy flooring cure properly.

The room where the epoxy is being installed must be clean, dry, and free of dust and debris. In addition, the temperature and humidity must be carefully monitored and controlled.

If the room is too cold, the epoxy will not cure properly.

Flooring Preparation

The fifth step in the epoxy flooring install process is to prepare the floor that the epoxy will be poured onto.

This step includes ensuring that the floor is clean, dry, and free of any surface defects.

Any cracks or pits in the surface must be repaired, and the entire area should be swept or vacuumed to remove any dirt or dust.

Once the floor is prepared, a primer can be applied to help ensure proper adhesion of the epoxy coating.

The primer should be allowed to dry completely before proceeding to the next step.

Mixing & Pigmenting Resin

After the floor has been cleaned and prepped, it's time to mix the epoxy resin and add pigments.

This is a critical step in the process, as the right ratio of resin to pigment will ensure a durable and long-lasting finish. The first step is to mix the two components together thoroughly.

Once they are fully combined, it's time to add the pigments. The amount of pigment added will depend on the desired color and level of opacity.

Once the pigments are added, the mixture must be stirred well to ensure an even distribution of color.

Finally, the mixture is ready to be applied to the floor.

Pouring & Curing Resin

The seventh step in the epoxy flooring installation process is Pouring & Curing the Resin itself. To ensure a strong bond and a durable finish, we take care to pay attention to a few key details during this step.

First, we make sure that the temperature in the room is in the ideal range according to manufacturer specifications, as extreme cold or heat can prevent the resin from curing properly.

We also make sure that there is plenty of ventilation, as fumes from the curing process can be harmful if inhaled. Once these conditions are met, we mix the resin according to the manufacturer's instructions and pour it onto the floor.

We then use a squeegee to spread the resin evenly, taking care to fill in any cracks or holes. Finally, we allow the resin to cure for the recommended amount of time before proceeding to the next step.

By taking care at this stage, we can ensure a high-quality epoxy finish that will last for years to come.

After Care

The final step in the process is any after care, like adding a top coat or sealant.

This helps to protect the floor from scuffs, scratches, and stains.

It also makes the floor easier to clean and helps to extend its lifespan.

We also take time to clean up the work area and do a quality assurance check of the product we have installed.

With proper care, your epoxy floor will look great and last for years to come.

Benefits of Epoxy Flooring

Epoxy flooring is a popular choice for both residential and commercial applications. Its durability and easy maintenance make it ideal for high-traffic areas, and its glossy finish can give any space a touch of style.

In addition to its aesthetic appeal, epoxy flooring also offers a number of practical benefits. It is slip-resistant, making it an ideal choice for wet areas such as bathrooms and kitchens.

It is also resistant to stains and scratches, making it a good choice for areas that see a lot of foot traffic. Epoxy flooring is also easy to clean and maintain, requiring only a damp mop or cloth for regular cleaning.

For these reasons, epoxy flooring is an increasingly popular choice for both homes and businesses.

How to Maintain Epoxy Floors

Epoxy floors are becoming increasingly popular in both residential and commercial settings. Thanks to their durability and easy maintenance, epoxy floors are ideal for high-traffic areas.

Here are some tips for keeping your epoxy floor looking its best:

- Sweep or Vacuum Regularly: The first step in keeping your epoxy floor clean is to sweep or vacuum it on a regular basis. This will help to remove any dirt, dust, or debris that has been tracked in.

- Mop as Needed: Mop your epoxy floor with a gentle cleaner as needed. Avoid using harsh chemicals, as these can damage the finish.

- Stain Removal: If you have a spill, it's important to clean it up immediately. For stubborn stains, you may need to use a mild abrasive cleaner. Be sure to test the cleaner in an inconspicuous area before using it on the entire floor.

With just a bit of routine cleaning, you can keep your epoxy floor looking like new for years to come.

How Much Does Epoxy Flooring Cost?

The cost of epoxy flooring installation can vary depending on a number of factors, including the type of epoxy being used, the size of the area being covered, and the amount of prep work required.

For example, a standard two-car garage will typically require less prep work than a commercial warehouse, and therefore will be less expensive to install. The type of epoxy also plays a role in price.

Basic epoxy floors will generally be less expensive than those made with more specialized materials. Finally, the cost of labor will also affect the overall price. In general, installation costs will be lower if the project can be completed in a single day.

However, larger or more complex projects may require multiple days to complete, resulting in higher labor costs.

By considering all of these factors, you can get a better idea of how much your epoxy flooring installation will cost.

Epoxy Flooring Louisville KY FAQs

How do you repair epoxy floors?

While epoxy floors are incredibly tough, they are not indestructible. Over time, the surface can become scratched or chipped. Fortunately, repairing an epoxy floor is relatively simple.

The first step is to clean the area around the damage to remove any dirt or debris. Next, use a putty knife or other sharp object to scrape away any loose pieces of epoxy.

Once the area is clear, mix together a new batch of epoxy resin and hardener according to the manufacturer's instructions.

Use a putty knife or trowel to apply the new mixture to the damaged area, taking care to smooth it out so that it matches the surrounding surface. Allow the repair to cure for 24 hours before walking on it.

How do you clean epoxy floors?

To keep your epoxy floor looking its best, it is important to clean it regularly. The first step is to sweep or vacuum the floor to remove any dirt or debris. Next, the floor should be mopped with a mild detergent.

For tough stains, you may need to use a scrub brush. Finally, the floor should be rinsed with clean water. Once the floor is dry, you can apply a fresh coat of epoxy for added protection.

What is an epoxy topcoat and why is it needed?

Epoxy is a coating made from a resin and hardener that is typically used on floors and other surfaces that need a durable, long-lasting finish.

Epoxy topcoats are usually clear or very lightly tinted, and they can be applied to a variety of materials, including concrete, metal, and wood. In addition to its durability, epoxy also has excellent moisture resistance and chemical resistance. It can also be used as a primer for other coatings, such as urethane.

Although epoxy topcoats are more expensive than other types of coatings, their superior performance makes them ideal for high-traffic areas or areas that require a tough finish.

How will my epoxy floor look a year or two down the line?

Epoxy floors are built to last, but that doesn't mean they're indestructible. Over time, they can become scratched or chipped, and the color may fade.

However, regular maintenance can help to extend the life of your epoxy floor. sweep or vacuum the floor on a daily basis to remove dirt and debris. once a week, mop the floor with a mild detergent.

If any scratches or chips appear, they can be repaired with a touch-up kit. With proper care, your epoxy floor will continue to look great for years to come.

What are the different types of epoxy floor coatings?

Epoxy floor coatings are a type of industrial flooring typically used in commercial and industrial settings.

There are three main types of epoxy floor coatings: 100% solid epoxy, solvent-based epoxy, and water-based epoxy. 100% solid epoxy is the most durable and longest lasting type of epoxy floor coating, but it is also the most expensive. Solvent-based epoxies are less durable than 100% solids, but they are less expensive and have a shorter cure time.

Water-based epoxies are the least durable type of epoxy floor coating, but they are the most affordable and have the shortest cure time. Epoxy floor coatings can be applied to concrete, wood, metal, and tile surfaces.

How long do epoxy floors last?

The answer depends on a number of factors, including the quality of the materials used, the thickness of the coating, and the level of traffic the floor will be subject to.

Generally speaking, epoxy floors can last anywhere from 5 to 10 years with proper care and maintenance. However, in high-traffic areas, the coating may need to be reapplied every 2-3 years to maintain its integrity.

With proper care and maintenance, epoxy floors can provide many years of service.

Reach Out For a Free Quote

Send us a message using the form below, and we’ll get back to you as soon as we can.

We will get back to you as soon as possible

Please try again later

Copyright © 2015-2022 JD Flooring Installers | All rights reserved

Contractor Website by Curated Leads